Reduced CO2 impact & logistics costs: Benefits for every step of the pharma cold chain

How thermal packaging innovator, Topa Thermal, quickly reduced CO2 impact & logistics costs for 3 companies delivering temperature sensitive pharmaceuticals.

Companies across many sectors have found that using a new design of pallet shipper to deliver temperature sensitive pharmaceuticals can cut costs, reduce CO2 impact and bring considerable efficiencies to their logistics operations in just one year. Here are 3 success stories.

Companies using °Connex OVERWRAP, a new thermal pallet shipper designed and manufactured by Topa Thermal, the Netherlands-based thermal packaging innovator, have found it is better for the planet, cuts freight costs and is more efficient for packing, handling and loading.

3 Case Studies – benefits of using °Connex OVERWRAP in your cold chain distribution

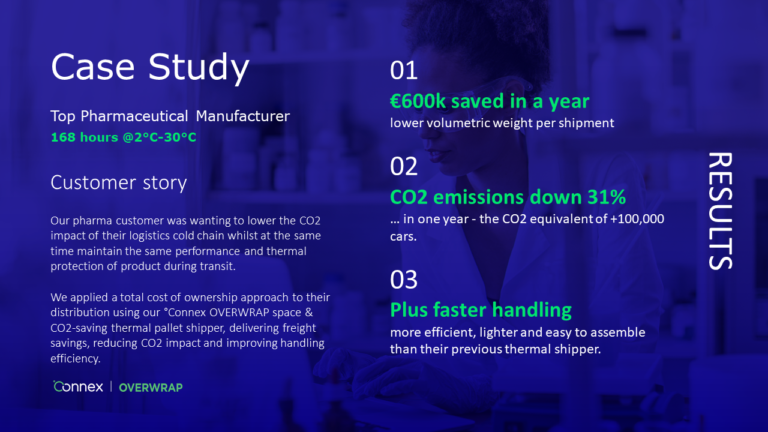

Case study 1: €600k annual saving for pharma manufacturer

Using our °Connex OVERWRAP flat-pack thermal shipper, we saved the customer €600,000 in freight costs and lowered CO2 emissions by 31% in one year. Now the logistics process is also faster, lighter and more efficient.

Case study 2: Packing time halved for pharma wholesaler

°Connex OVERWRAP by Topa Thermal halved packing time for this international wholesaler and cut shipping costs by 40%. Also, their total logistics benefited from lower CO2 due to fewer shipments, and a light-weight, high capacity packaging system made from sustainable and reusable materials.

Case study 3: Freight cost down 35% for logistics company

For this logistics provider and distribution company delivering temperature sensitive healthcare products, Topa Thermal was able to cut the billable weight by a third and cut freight costs even further by shipping more product per load. The new thermal packaging solution gives the added benefit of handling efficiencies, quicker packing and optimised size for direct-to-rollerbed loading.

Case Study-how a thermal packaging manufacturer helped 3 pharma cold chain companies

“Smart Thermal Packaging Solution for Improved Impact on CO2 Emissions in Bulk Pharma Distribution”

BSMA Sustainability Supply Chain Award Finalist 2022